What Is Nylon Fabric? From Stockings to Space Suits

You’ve likely felt nylon’s smooth, strong touch in your favorite rain jacket or gym leggings, but what exactly gives this fabric its unique power?

I will break down the science and practicality of this synthetic wonder, covering its surprising wartime origin, the chemistry of its creation, the main types you encounter, the key properties that define its performance, and its vast range of modern uses.

| Breathability | Low | Nylon fibers are non-absorbent and closely woven, trapping heat and moisture against the skin. |

| Shrinkage Rate | Very Low | Minimal with proper care. Heat and agitation can cause distortion, not true shrinkage. |

| Heat Tolerance | Low | Melts around 400°F (204°C). Never use high-heat irons or dryers. |

| Stretch Factor | Medium to High | Has excellent recovery in knitted forms. Woven nylon has little inherent stretch. |

| Water Resistance | High | Fibers repel water, making it quick-drying. A tight weave enhances this property. |

| Dye Affinity | Medium | Requires specific acid or disperse dyes and high heat to bond color effectively. |

Where Did Nylon Come From? A Lab-Born Revolution

Nylon didn’t grow in a field or come from an animal. It was born from a test tube. In the 1930s, a brilliant chemist named Wallace Carothers and his team at DuPont were experimenting with polymers-long chains of molecules. Their goal was to engineer a brand new material.

They succeeded beyond dreams. In 1935, they created the first fully synthetic fiber, pulling a strand from a glass rod that was stronger and more elastic than any natural silk. This was a fabric designed from the ground up, not discovered in nature. Its first major use was in parachutes for World War II, proving its incredible strength and reliability.

Think about how different this is from cotton or wool. Those fibers vary with the season, the soil, the animal’s health. A lab-made polymer like nylon is consistent. Every batch has the same properties because we control the recipe. This origin story explains everything about nylon: its uniform strength, its predictable behavior, and why it doesn’t breathe like a natural fiber. It was built for performance, not comfort.

What is Nylon Made Of? It Starts With a Molecule

At its core, nylon is a polyamide. That’s the scientific family name. You can think of “poly” meaning many, and “amide” referring to the specific type of chemical link that holds it all together. The raw materials for these chemicals come from petroleum.

In practical terms, when people ask “are nylon and polyamide the same thing?”, the answer is generally yes-nylon is the common name for a specific group of synthetic polyamides. You might see “polyamide” on a European clothing label, while “nylon” is more common in the US, but they refer to the same basic synthetic fiber.

To picture it, imagine a long, long chain of plastic pop-beads. Each individual bead is a molecule. In a lab, chemists link thousands of these molecular “beads” together end-to-end to form a polymer chain. This chain is the fundamental structure of the fiber. The longer and more orderly the chain, the stronger the final nylon filament tends to be.

This leads to another common question: are nylon and plastic the same? They are cousins. Both are synthetic polymers, but they have different chemical recipes and structures. Think of it like different recipes for dough-one becomes a chewy bagel (nylon), another becomes a crisp cracker (polyester). They share origins but have distinct properties.

Here’s where textile science gets hands-on. Those long polymer chains are heated until they melt into a thick, honey-like liquid. This liquid is then forced through a tiny showerhead-like device called a spinneret. As each fine stream of molten polymer hits the cool air, it solidifies into a continuous filament. This process, called melt spinning, is how we create the smooth, strong filaments that are then wound onto spools, stretched to align the molecules for extra strength, and finally woven or knitted into the fabric you know.

From a care perspective, knowing this origin story explains everything. That melt-spun origin is why heat is nylon’s biggest enemy. I always tell people: nylon doesn’t shrink like cotton; it melts. A hot iron or dryer can permanently fuse fibers together or create shiny, scorched patches. For washing, use cool or warm water, never hot. For dyeing, you need special disperse dyes and near-boiling water to temporarily open up those tightly packed chains for color-it’s a process best done with great care and ventilation.

Nylon Types You’ll Actually Meet: From Nylon 6 to Ballistic Weave

You’ll often hear nylon described by numbers, like Nylon 6 or Nylon 6,6. It sounds technical, but the difference is simple. The number refers to the count of carbon atoms in the starting chemical chain. Think of it like building a fence. Nylon 6 uses a 6-carbon link as its starting post, while Nylon 6,6 uses two different 6-carbon links. This small change in the foundation makes Nylon 6,6 molecules pack together more tightly. The result is that Nylon 6,6 has a slightly higher melting point and is often considered more durable, while Nylon 6 is known for better dyeability and elasticity. In practice, you won’t feel a huge difference in your jacket, but it matters for engineers and mills choosing the right fiber for the job.

For Apparel: Softness and Stretch

Here, nylon is engineered for comfort against your skin. It’s often texturized, meaning the smooth filament is crimped or looped to create bulk, softness, and breathability.

- Tactel: This isn’t a single fabric, but a family of premium nylon fibers by Invista. Tactel yarns can be made to feel like cotton, have a silky sheen, or provide exceptional moisture-wicking. You’ll find it in high-end travel clothing and performance underwear.

- Supplex: Another Invista brand, Supplex is a type of air-textured nylon. The process makes the fibers more cotton-like, giving the fabric a softer hand and better breathability than standard flat nylon, while retaining its strength and quick-dry properties. It’s common in swimwear, windbreakers, and lightweight hiking pants.

- Air-Textured Nylon: This is the general process behind fabrics like Supplex. High-speed air jets tangle the filaments, creating tiny loops that give the yarn volume. This texture is what makes apparel nylon feel less plastic-like and more wearable.

Are jerseys made of nylon? Sometimes. While classic cotton jersey is king for t-shirts, many athletic and moisture-wicking jerseys blend nylon with polyester or spandex. The nylon adds a soft feel and durability to the stretchy knit.

For Heavy-Duty Use: Maximum Abrasion Resistance

This is where nylon’s legendary strength is put to the test. These fabrics have a stiff, boardy hand and a pronounced, rugged weave.

- Cordura: A famous brand of high-tenacity nylon fabric known for extreme abrasion resistance. It’s not one specific weave, but a certification of durability. You’ll recognize its rugged texture on motorcycle gear, heavy-duty backpacks, luggage, and workwear. Care for Cordura is simple: wipe clean or machine wash cool, but avoid high heat in dryers as it can weaken the fibers over time.

- Ballistic Nylon: Originally developed for flak jackets, this is a thick, dense 2×2 basket weave. It’s less common now in true ballistic applications but lives on in luggage, motorcycle gear, and protective knife sheaths. Its main visual cue is the square, checkerboard-like weave pattern.

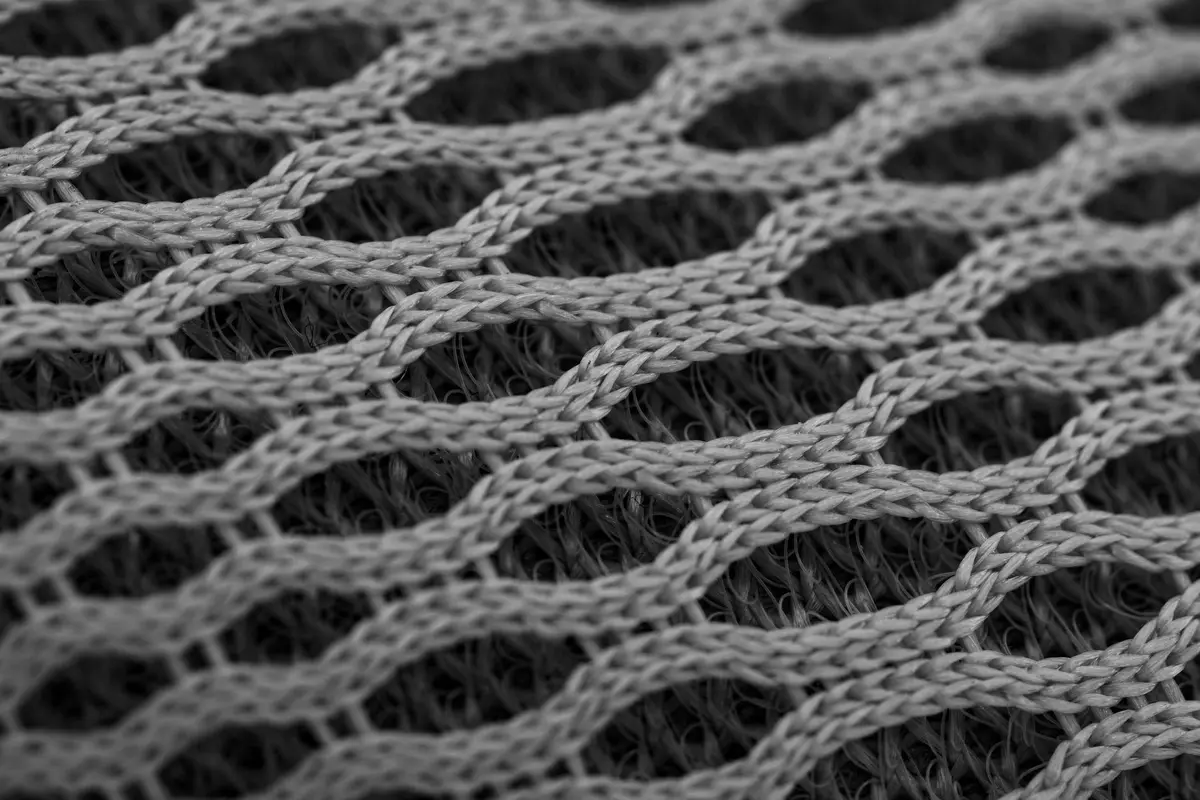

- Climbing Rope & Webbing: This is core-strength nylon. The fibers are drawn to an extremely high tenacity and then woven or braided into a dense, unyielding structure. It has minimal stretch under load, which is exactly what you need for safety gear. This nylon type is sensitive to chemicals and UV degradation, so care is specialized.

For Sheer Fabrics: Delicate Strength

Nylon’s ability to be drawn into incredibly fine, strong filaments makes it perfect for sheer applications. A single denier of nylon (a unit of fineness) can be much finer than a human hair.

- Hosiery & Tights: Almost all sheer stockings are made from a fine knit of nylon filaments, often blended with spandex (Lycra) for fit. The biggest care tip here is to always hand-wash in cool water with a gentle detergent and lay flat to dry; the heat and agitation of a machine will destroy them quickly.

- Tricot: This is a specific warp-knit, often used for lingerie linings, sleepwear, and the inner layer of swimsuits. It has a slight stretch in one direction, a smooth face, and a textured back. It’s durable for its weight but can snag easily on rough surfaces.

Dyeing these sheer nylons at home is possible with acid dyes (the same type used for wool and silk), but you must be gentle. Use a low simmer, not a rolling boil, and agitate very carefully to avoid tangling and distortion.

How Nylon Behaves: The Good, The Tough, and The Heat-Sensitive

In the lab, we describe nylon by its technical polymer traits. In your hands, you feel its practical personality. Here’s how its core properties translate directly to the way you wash, wear, and care for it.

Exceptional Strength & Elasticity

Nylon’s strength isn’t rigid like a metal rod. It’s the strength of a spring. Under tension, the long polymer chains slide and stretch. This elastic recovery is why a nylon climbing rope can catch a fall and a pair of stockings can hug your shape without sagging. Compare it to cotton, which stretches more like taffy-slowly and with less spring-back. This same property makes finished nylon fabrics resistant to tearing, but it has a trade-off. That tough fiber can be sharp when broken, leading to snags and, over time, the dreaded “pills” on the surface as tiny broken fibers ball up.

My care tip for this? Wash nylon items inside out in a mesh bag. This protects the surface from abrasion with other items in the drum, which is the main cause of pilling. A front-loading washer is gentler than a top-loader with an agitator.

Quick-Drying & Water-Resistant

Nylon is hydrophobic-it fears water. Drop water on it, and the droplets bead up and roll off instead of soaking in. This is perfect for a rain jacket shell but terrible for a workout shirt meant to wick sweat. Because it doesn’t absorb moisture, nylon dries incredibly fast, often in just a couple of hours when air-dried. For washing, this means you can use a low-heat tumble dry cycle briefly and then hang it up; it will be dry in no time. Avoid fabric softeners, as they can coat the fibers and reduce this water-resistant quality.

Heat Sensitivity: The Critical Limitation

This is the most important care factor. Nylon is a thermoplastic. It doesn’t burn like cotton; it melts. That melting point starts around 428°F (220°C), but damage can occur at much lower temperatures in your laundry room. High heat from a dryer or iron can cause irreversible shine, stiffness, or even a melted, wavy texture on your garment. I’ve seen backpacks warp from being left in a hot car.

Always treat nylon with cool to warm heat:

- Washing: Use cold or warm water (not hot).

- Drying: Low heat tumble dry or, better yet, air dry.

- Ironing: If you must, use the lowest “synthetic” setting and iron quickly. Place a thin cotton cloth, like a pillowcase, between the iron and the nylon as a buffer.

Poor UV Resistance

Sunlight is nylon’s kryptonite. Ultraviolet radiation attacks the polymer chains, breaking them down. You’ll see this as fading colors and, more critically, as the fabric becoming brittle and losing its strength. That’s why an old nylon flag left outdoors shreds so easily. For outdoor gear like jackets or tent mesh, look for fabrics labeled as “UV-stabilized.” For everyday items, simple habits help: dry your activewear in the shade, not in direct sun, and store seasonal gear out of bright light.

Dyeability

Nylon accepts color beautifully, but it plays by specific rules. The dye sites in the fiber are chemically similar to those in wool and silk. This means nylon requires acid dyes, not the all-purpose dyes meant for cotton, and the dye bath must be near boiling to permanently set the color. This is why home dyeing nylon can be tricky-the heat required is very close to the point where the fabric can be damaged. In production, this is tightly controlled. For you, the key takeaway is about care: because the dye is so firmly set with heat, properly dyed nylon is very colorfast in normal washing. You’ll rarely see bleeding or fading in the wash if you use cool water. This is a clear example of fabric dyes permanence in action. When the dye bonds securely to nylon, the color remains stable through ordinary washing.

What Do We Use Nylon For? From Your Jacket to Your Gear

Nylon isn’t just one thing. Its magic lies in how it’s spun and processed, which lets designers tap into different superpowers for wildly different jobs. I like to think of it like this: the same basic polymer can become a featherweight rope or a sleek stocking, all based on the recipe and machinery. Let’s break down its biggest roles by the property that makes them work.

Strength + Lightweight: The Invisible Workhorse

This is nylon’s original claim to fame. Pound for pound, a nylon filament is stronger than steel wire. When you need high tensile strength without the weight penalty, nylon is the go-to.

Think of items that must not fail under stress. Parachutes and climbing ropes rely on this incredible strength-to-weight ratio to save lives. Your backpack, luggage, and even your dog’s leash use thick, woven nylon webbing for the same reason-it can take a beating without tearing and it barely adds any heft.

In the lab, we measure this in denier (the weight of the yarn). A high-denier nylon weave feels rugged and is almost impossible to rip by hand.

Elasticity + Softness: The Second Skin

Here, nylon shows its other personality. When drawn into fine, smooth filaments and knit tightly, it gains a gentle stretch and a soft, almost slippery hand. This is the nylon you wear.

It’s the foundation of sheer hosiery and sleek leggings, providing a smooth, forgiving fit. For swimwear, that inherent elasticity combined with excellent chlorine resistance makes it a staple. I often reference that sleek, synthetic look in films-think of the cool, minimalist aesthetic of a “A Simple Favor”-that’s often fine, opaque nylon at work.

This version of nylon is all about drape and recovery, bouncing back to its original shape after stretching.

Water Resistance: The Protective Shell

Nylon itself isn’t waterproof, but it’s naturally water-resistant. The smooth filament fibers have low absorbency, so water beads up and rolls off instead of soaking in immediately. This makes it a perfect base fabric for protective outer layers.

Most raincoats, windbreakers, and umbrella canopies are made from tightly woven nylon. It’s often coated with a polymer (like polyurethane) or laminated with a membrane to become fully waterproof. Tent floors use thick, coated nylon to keep ground moisture out.

Care tip: The water resistance is in the coating. Always wash these items on a gentle cycle with a technical cleaner, and never use fabric softener or high heat, which can degrade the protective layer.

The Power of Blends: Making Other Fibers Better

Rarely used alone in everyday garments, nylon is a master team player. Blending it with other fibers, such as wool, creates fabrics that outperform their individual components.

- Nylon + Cotton: Common in socks and heavy-duty workwear. The cotton provides breathability and softness, while just 10-20% nylon dramatically increases abrasion resistance and durability. Your socks last months longer.

- Nylon + Spandex (Lycra): The classic activewear blend. Nylon provides the soft, quick-drying structure, while spandex adds the extreme, multi-directional stretch. This is your yoga pants and swimsuit fabric.

- Nylon + Wool: A smart blend for sweaters, socks, and suiting. The wool offers warmth and natural feel, while the nylon reinforces high-stress areas like elbows, heels, and knees, reducing holes and extending the garment’s life.

When caring for blends, always defer to the needs of the most delicate fiber in the mix. If it’s a wool-nylon sweater, wash it like wool-cool water, gentle cycle, lay flat to dry.

The Moda Material Care Protocol: Washing, Drying, and Ironing Nylon

Think of nylon like a spring. It’s incredibly resilient and wants to bounce back to its original shape, but too much heat can permanently weaken its structure. This guide isn’t just about following a tag, it’s about understanding the polymer science so your gear lasts.

Your Step-by-Step Guide to Nylon Care

Follow this sequence to protect your fabric’s strength and appearance.

- Washing

I always start with cool to warm water, never exceeding 30°C or 85°F. Hot water doesn’t clean nylon better, it just encourages dye migration and stresses the fibers.

Use the gentle cycle on your machine. This minimizes the abrasion that can cause pilling, especially on nylon blends.

Choose a standard liquid detergent meant for synthetic fabrics; powders can sometimes leave residues that dull the sleek hand of nylon. Avoid chlorine bleach completely. It doesn’t just weaken nylon, it causes a chemical reaction that turns the fabric a permanent, ugly yellow. Bleach can cause yellowing in polyester and spandex blends, and nylon isn’t immune. To keep colors true, avoid chlorine bleach on these fabrics.

- Drying

Heat is nylon’s true enemy. In the dryer, use the lowest heat setting possible. High heat doesn’t just dry the fabric, it can actually melt the fine fiber ends.

This melting creates shiny, hard “scorch” marks that you cannot fix. To be absolutely safe, line drying is my non-negotiable recommendation for delicate nylon items like lingerie or ultralight shells. It prevents all heat damage and preserves elasticity.

If you must tumble dry, remove the item immediately when the cycle ends. Letting it sit crumpled in the heat sets in deep wrinkles.

- Ironing

You often won’t need to iron nylon if you dry it properly. If you must, set your iron to the lowest synthetic setting-often labeled “Cool” or “Warm.”

Always use a pressing cloth, like a thin cotton handkerchief, between the iron and the nylon. Never let the hot iron sit in one spot, as the heat can quickly build up and melt the fabric, leaving an iron-shaped gloss or burn.

Does Nylon Shrink? The Direct Answer.

Nylon can experience minimal shrinkage from washing and drying, typically only 1-3%, if heat is poorly controlled. The major distortion people mistake for shrinkage is actually localized melting and fiber damage from high heat. Unlike cotton, which shrinks when its fibers swell and contract, nylon is a thermoplastic. It doesn’t shrink like a sponge; it warps like a plastic bag held near a flame. Control the heat, and you control the shape.

Hands-On Troubleshooting & Pro Tips

In the lab, we test for nylon’s infamous static cling by rubbing it with wool. At home, a small dab of fabric softener in a final rinse or a dedicated anti-static spray can help.

If you get a snag, don’t pull it. Gently work the snagged thread back through to the wrong side of the fabric using a blunt needle.

To test if an unknown fabric contains nylon, perform a careful burn test: nylon melts and beads, smells like celery, and leaves a hard, tan bead. It self-extinguishes when removed from the flame.

For dyeing, remember nylon has a strong affinity for acid dyes, the same type used on wool and silk. This means you can often successfully dye nylon fabrics at home with proper acid dye and vinegar, but the color may not be as lightfast as the original factory dye.

Hands-On with Nylon: Dyeing and Troubleshooting Common Issues

Moving from theory to practice is where your fabric knowledge pays off. Nylon behaves very differently from fibers like cotton, especially when you try to change its color or fix a problem. I’ve spent many hours at the dye pot with this fiber, and here’s what you need to know.

Home Dyeing Guide

You cannot dye nylon with the same products you use for cotton. Cotton readily absorbs fiber-reactive dyes in cold water. Nylon is stubborn. It requires acid dyes and significant heat.

Think of nylon’s molecular structure as a tightly coiled spring. You need heat to make it relax and open up so dye molecules can enter. For successful home dyeing, you must use acid dyes (the same type used for wool and silk) and maintain water at a near-simmering 180-200°F for at least 30 minutes. The acidic environment, usually created with white vinegar or citric acid, helps the dye bond to the fiber. Even then, nylon can be tricky to dye evenly by hand.

Safety is non-negotiable. Work in a well-ventilated area, use a pot dedicated only to dyeing, and wear gloves and a mask. Unlike a simple cotton tie-dye project, dyeing nylon is a stovetop operation.

Troubleshooting Nylon

Even with careful care, issues pop up. Here’s how to identify and address the most common ones.

Heat Damage and Melting

This is the most catastrophic failure for nylon. If you’ve ever accidentally touched a nylon jacket to a hot pan or had an iron on too high a setting, you’ve seen it. The fabric develops shiny, hard, often discolored spots. The fibers have literally melted and fused together. Heat damage is permanent and irreversible; the only fix is patching or repurposing the fabric. Note that nylon’s heat resistance isn’t unlimited; it can burn if exposed to very high temperatures. Understanding these limits helps explain the burning risk and informs safer care for nylon fabrics. Always use a low-heat or cool iron, and keep nylon far from direct flames or high-heat dryers.

Yellowing

White or light-colored nylon often develops a dull yellow cast. The usual culprits are chlorine bleach or prolonged sun exposure (UV degradation). If bleach caused it, the damage is likely chemical and permanent. For general discoloration, try a long soak in a solution of oxygen-based, color-safe bleach and warm water. Understanding nylon fabric chemicals safety can help you avoid these pitfalls. Choosing cleaners labeled nylon-safe can protect fibers and color. Never use chlorine bleach on nylon, as it weakens the fibers and worsens yellowing.

Dye Bleed and Color Transfer

Nylon, especially in its bright athleticwear forms, can sometimes release dye. To prevent initial bleed, wash new vibrant nylon items separately in cool water with a color-catcher sheet. If dye has transferred onto another piece of fabric, act quickly. Soak the affected garment in a solution of cool water and oxygen-based bleach. For set-in stains, a paste of detergent and baking soda gently rubbed on the spot can sometimes lift it.

Pilling

Pure nylon fabrics resist pilling well, but nylon blends-particularly with cotton or wool-are prone to those annoying little fabric balls. They form from surface fibers tangling. Understanding the causes of pilling can guide prevention and removal choices. Use a battery-operated fabric shaver or a sweater stone to safely remove pills; a razor can easily snag and cut the underlying fabric. Wash the garment inside-out on a gentle cycle to minimize future friction.

Is Nylon the Same as Ethilon?

You might see this term in specialized contexts. Ethilon is not a different fiber. Ethilon is a brand name for a specific type of nylon suture used in surgery. It’s a testament to nylon’s strength, smoothness, and biocompatibility. So while all Ethilon is nylon, not all nylon is Ethilon-it’s just a highly refined, medical-grade version of the same synthetic polymer.

Last Notes on the Nylon Fiber Family

The single most important rule for handling nylon is to respect its sensitivity to heat. Always wash and dry your nylon items on the lowest heat settings, or better yet, let them air dry completely away from direct sunlight. This one habit prevents most common nylon failures, from permanent shrinkage to that stiff, brittle feel.

View your durable nylon gear as a long-term commitment. When a nylon item finally wears out, consider if it can be patched, repurposed into a stuff sack or rag, or properly recycled through a textile program, keeping it out of landfill for as long as possible. Your care choices directly extend the life of the material, and learning how nylon behaves in blends with cotton or wool makes you a more informed fabric user. This is especially important considering ongoing discussions about nylon’s eco-friendliness and biodegradability.

Related Guides and Information

- What is Nylon Fabric: Properties, How its Made and Where | Sewport

- Nylon – Wikipedia

- 4 Uses of Nylon and Their Differences

- Nylon Fabric – Everything You Need To Know

- Benefits of Using Nylon Fabric: From Invention to Everyday Use

- Nylon – TextileR: Future Textile Industries

Florian Ventura

Florian is a high fashion blog writer, fashion and fabric expert and a keen expert in fabric, clothing and materials. She has worked in large textile and fashion houses for over 10+ years, engineering and working with various fabric types and blends. She is an expert when it comes to questions on any and all kinds of fabrics like linen, cotton, silk, jute and many more. She has also traveled around the world studying traditional fabrics and aims to bring them into the modern fashion use.